ASTM D3261-16

(Specification)Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

ABSTRACT

This specification covers polyethylene (PE) butt fusion fittings for use with polyethylene pipe (IPS and ISO) and tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure. Pressure strength test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers polyethylene (PE) butt fusion fittings for use with polyethylene pipe (IPS, DIPS, and ISO) and tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D3261 −16 An American National Standard

Standard Specification for

Butt Heat Fusion Polyethylene (PE) Plastic Fittings for

1

Polyethylene (PE) Plastic Pipe and Tubing

This standard is issued under the fixed designation D3261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* F2206 Specification for Fabricated Fittings of Butt-Fused

Polyethylene (PE)

1.1 This specification covers polyethylene (PE) butt fusion

fittings for use with polyethylene pipe (IPS, DIPS, and ISO) 2.2 Federal Standard:

3

and tubing (CTS). Included are requirements for materials, Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

workmanship, dimensions, marking, sustained pressure, and

2.3 Military Standard:

burst pressure. 3

MIL-STD-129 Marking for Shipment and Storage

1.2 The values stated in inch-pound units are to be regarded

2.4 National Sanitation Foundation Standard:

as standard. The values given in parentheses are mathematical

Standard No. 14 for Plastic Piping Components and Related

4

conversions to SI units that are provided for information only

Materials

and are not considered standard.

5

2.5 Plastic Pipe Institute

1.3 This international standard was developed in accor-

PPI TR-3 Policies and Procedures for Developing Hydro-

dance with internationally recognized principles on standard-

static Design Basis (HDB), Pressure Design Basis (PDB),

ization established in the Decision on Principles for the

Strength Design Basis (SDB), and Minimum Required

Development of International Standards, Guides and Recom-

Strength (MRS) Ratings for Thermoplastic Piping Mate-

mendations issued by the World Trade Organization Technical

rials or Pipe7

Barriers to Trade (TBT) Committee.

PPI TR-4 HDB/SDB/PDB/MRS Listed Materials, PPI List-

ing of Hydrostatic Design Basis (HDB), Strength Design

2. Referenced Documents

Basis(SDB),PressureDesignBasis(PDB),andMinimum

2

2.1 ASTM Standards: Required Strength (MRS) Ratings for Thermoplastic Pip-

D1598 Test Method for Time-to-Failure of Plastic Pipe ing Materials or Pipe

Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic 3. Terminology

Pressure of Plastic Pipe, Tubing, and Fittings

3.1 Definitions are in accordance with Terminology F412

D1600 Terminology forAbbreviatedTerms Relating to Plas-

and abbreviations are in accordance with Terminology D1600,

tics

unless otherwise specified.

D2122 Test Method for Determining Dimensions of Ther-

3.2 Definitions:

moplastic Pipe and Fittings

3.2.1 butt fusion fitting, n—afittinghaveoneormoreoutlets

D2513 Specification for Polyethylene (PE) Gas Pressure

Pipe, Tubing, and Fittings that can be butt fusion joined to pipe, tubing, or fitting.

D3350 Specification for Polyethylene Plastics Pipe and Fit-

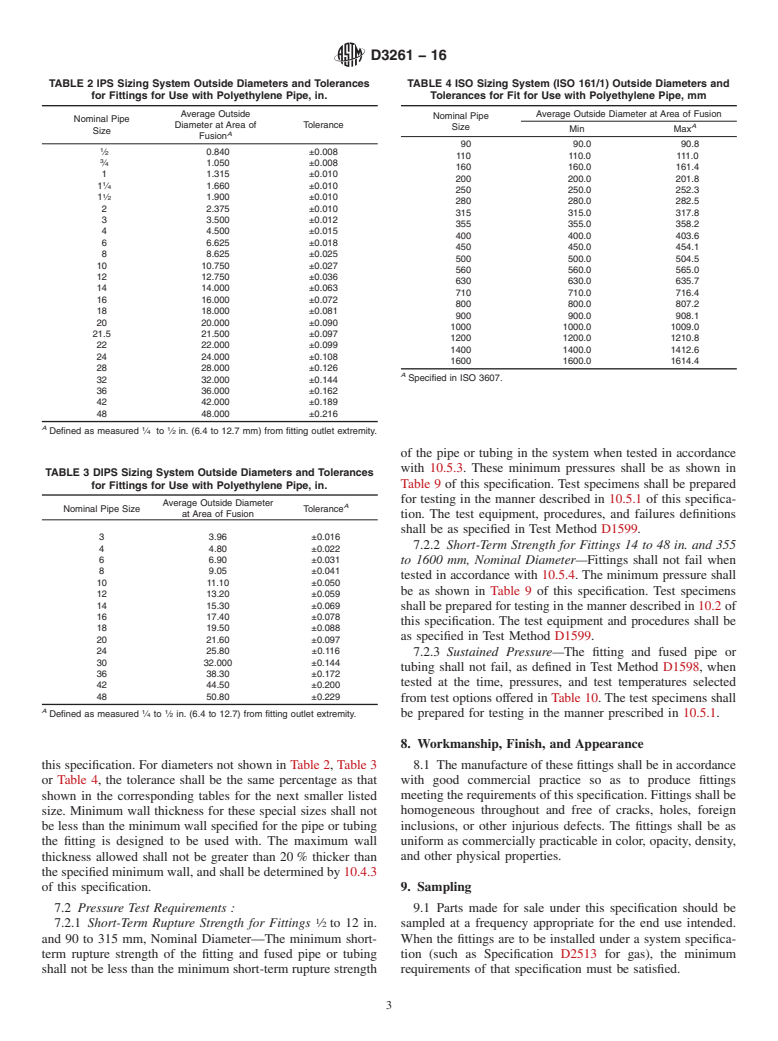

3.2.2 dimensionratio(DR)forthermoplasticpipe—theratio

tings Materials

of diameter to wall thickness. For this specification it is

F412 Terminology Relating to Plastic Piping Systems

calculated by dividing the specified outside diameter by the

specified wall thickness of the fitting at its area of fusion. DRs

are rounded and do not calculate exactly.

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved Nov. 1, 2016. Published November 2016. Originally

3

approved in 1973. Last previous edition approved in 2015 as D3261 – 15. DOI: DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

10.1520/D3261-16. 19111-5094 http://quicksearch.dla.mil/

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Arbor, MI 48113-0140, http://www.nsf.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

the ASTM website. Irving, TX 75062, http://www.plasticpipe.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

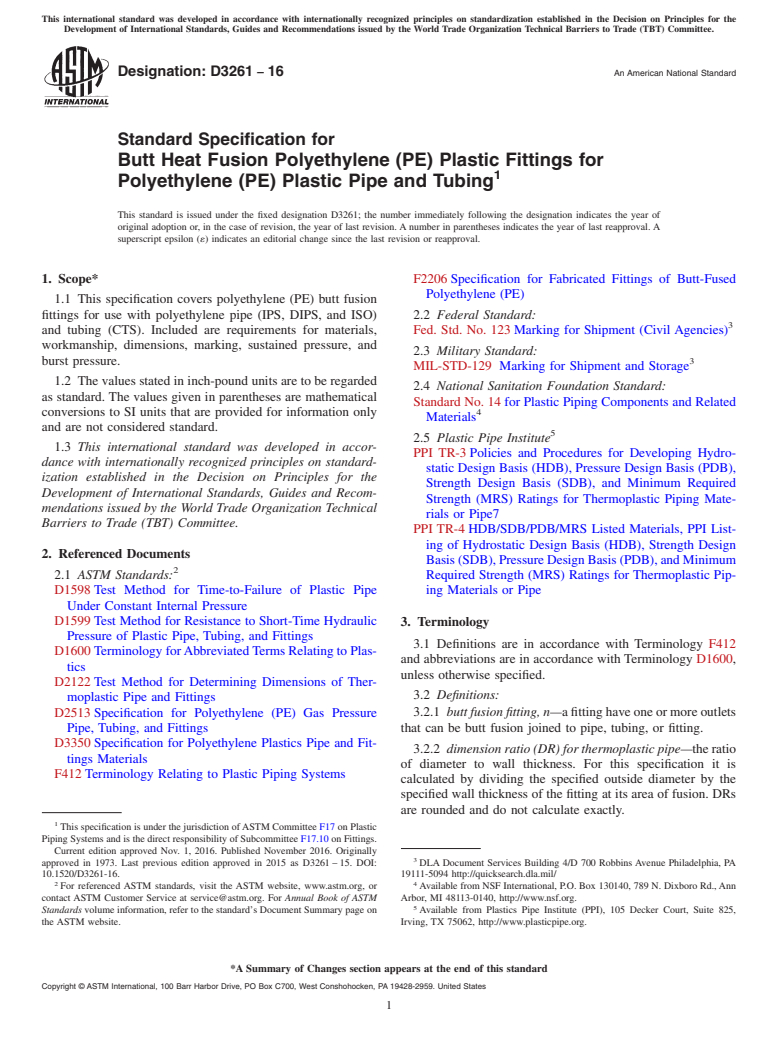

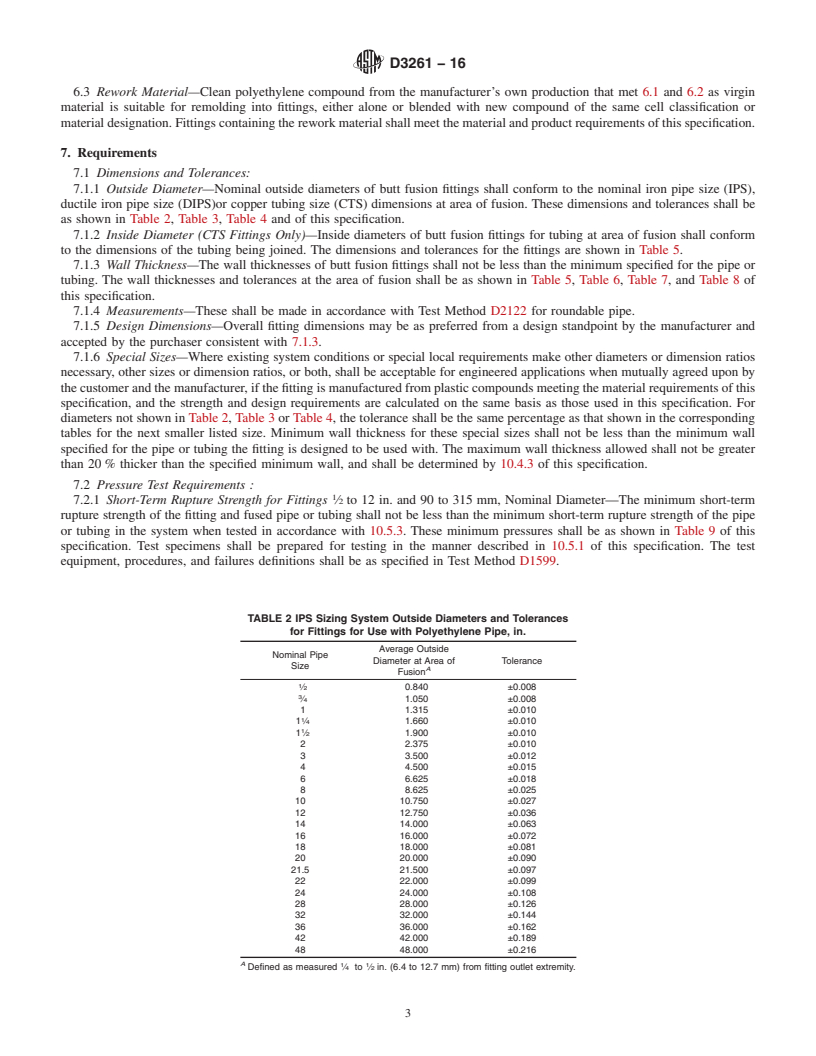

D3261−16

4. Classification E.CodeCmaterialcompoundsshallhave2to3percentcarbon

black. Code E material compounds shall be colored with UV

4.1 General—This specification covers

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3261 − 15 D3261 − 16

Standard Specification for

Butt Heat Fusion Polyethylene (PE) Plastic Fittings for

1

Polyethylene (PE) Plastic Pipe and Tubing

This standard is issued under the fixed designation D3261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers polyethylene (PE) butt fusion fittings for use with polyethylene pipe (IPS, DIPS, and ISO) and

tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2513 Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F412 Terminology Relating to Plastic Piping Systems

F2206 Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE)

2.2 Federal Standard:

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Military Standard:

3

MIL-STD-129 Marking for Shipment and Storage

2.4 National Sanitation Foundation Standard:

4

Standard No. 14 for Plastic Piping Components and Related Materials

5

2.5 Plastic Pipe Institute

PPI TR-3 Policies and Procedures for Developing Hydrostatic Design Basis (HDB), Pressure Design Basis (PDB), Strength

Design Basis (SDB), and Minimum Required Strength (MRS) Ratings for Thermoplastic Piping Materials or Pipe7

PPI TR-4 HDB/SDB/PDB/MRS Listed Materials, PPI Listing of Hydrostatic Design Basis (HDB), Strength Design Basis

(SDB), Pressure Design Basis (PDB), and Minimum Required Strength (MRS) Ratings for Thermoplastic Piping Materials

or Pipe

3. Terminology

3.1 Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600, unless

otherwise specified.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved Dec. 15, 2015Nov. 1, 2016. Published January 2016November 2016. Originally approved in 1973. Last previous edition approved in 20122015

ɛ1

as D3261 – 12D3261 – 15. . DOI: 10.1520/D3261-15.10.1520/D3261-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA 19111-5094 http://quicksearch.dla.mil/

4

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann Arbor, MI 48113-0140, http://www.nsf.org.

5

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825, Irving, TX 75062, http://www.plasticpipe.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3261 − 16

3.2 dimension ratio (DR) for thermoplastic pipe—the ratio of diameter to wall thickness. For this specification it is calculated

by dividing the specified outside diameter by the specified wall thickness of the fitting at its area of fusion. DRs are rounded and

do not calculate exactly.

3.2 Definitions:

3.2.1 butt fusion fitting, n—a fitting have one or more outlets that can be butt fusion joined to pipe, tubing, or fitting.

3.2.2 dimension ratio (DR) for thermoplastic pipe—the ratio of diameter to wall thickness. For this specification it is calculated

by dividing the specified outside diameter by the specified wall thickness of the fitting at its area

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3261 − 16 An American National Standard

Standard Specification for

Butt Heat Fusion Polyethylene (PE) Plastic Fittings for

1

Polyethylene (PE) Plastic Pipe and Tubing

This standard is issued under the fixed designation D3261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* F2206 Specification for Fabricated Fittings of Butt-Fused

Polyethylene (PE)

1.1 This specification covers polyethylene (PE) butt fusion

fittings for use with polyethylene pipe (IPS, DIPS, and ISO) 2.2 Federal Standard:

3

and tubing (CTS). Included are requirements for materials, Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

workmanship, dimensions, marking, sustained pressure, and

2.3 Military Standard:

burst pressure. 3

MIL-STD-129 Marking for Shipment and Storage

1.2 The values stated in inch-pound units are to be regarded

2.4 National Sanitation Foundation Standard:

as standard. The values given in parentheses are mathematical

Standard No. 14 for Plastic Piping Components and Related

conversions to SI units that are provided for information only 4

Materials

and are not considered standard.

5

2.5 Plastic Pipe Institute

1.3 This international standard was developed in accor-

PPI TR-3 Policies and Procedures for Developing Hydro-

dance with internationally recognized principles on standard-

static Design Basis (HDB), Pressure Design Basis (PDB),

ization established in the Decision on Principles for the

Strength Design Basis (SDB), and Minimum Required

Development of International Standards, Guides and Recom-

Strength (MRS) Ratings for Thermoplastic Piping Mate-

mendations issued by the World Trade Organization Technical

rials or Pipe7

Barriers to Trade (TBT) Committee.

PPI TR-4 HDB/SDB/PDB/MRS Listed Materials, PPI List-

ing of Hydrostatic Design Basis (HDB), Strength Design

2. Referenced Documents

Basis (SDB), Pressure Design Basis (PDB), and Minimum

2

2.1 ASTM Standards: Required Strength (MRS) Ratings for Thermoplastic Pip-

D1598 Test Method for Time-to-Failure of Plastic Pipe ing Materials or Pipe

Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic

3. Terminology

Pressure of Plastic Pipe, Tubing, and Fittings

3.1 Definitions are in accordance with Terminology F412

D1600 Terminology for Abbreviated Terms Relating to Plas-

and abbreviations are in accordance with Terminology D1600,

tics

unless otherwise specified.

D2122 Test Method for Determining Dimensions of Ther-

3.2 Definitions:

moplastic Pipe and Fittings

D2513 Specification for Polyethylene (PE) Gas Pressure 3.2.1 butt fusion fitting, n—a fitting have one or more outlets

that can be butt fusion joined to pipe, tubing, or fitting.

Pipe, Tubing, and Fittings

D3350 Specification for Polyethylene Plastics Pipe and Fit-

3.2.2 dimension ratio (DR) for thermoplastic pipe—the ratio

tings Materials

of diameter to wall thickness. For this specification it is

F412 Terminology Relating to Plastic Piping Systems

calculated by dividing the specified outside diameter by the

specified wall thickness of the fitting at its area of fusion. DRs

are rounded and do not calculate exactly.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved Nov. 1, 2016. Published November 2016. Originally

3

approved in 1973. Last previous edition approved in 2015 as D3261 – 15. DOI: DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

10.1520/D3261-16. 19111-5094 http://quicksearch.dla.mil/

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Arbor, MI 48113-0140, http://www.nsf.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

the ASTM website. Irving, TX 75062, http://www.plasticpipe.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3261 − 16

4. Classification E. Code C material compounds shall have 2 to 3 percent carbon

black. Code E material compounds shall be colored with UV

4.1 General—This specification covers butt fusion fittings

stabilizer.

intended for use with polyethylene pipe and tubing.

4.1.1 Fitting

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.