ASTM E2799-22

(Test Method)Standard Test Method for Testing Disinfectant Efficacy against Pseudomonas aeruginosa Biofilm using the MBEC Assay

Standard Test Method for Testing Disinfectant Efficacy against <emph type="bdit">Pseudomonas aeruginosa</emph> Biofilm using the MBEC Assay

SIGNIFICANCE AND USE

5.1 Vegetative biofilm bacteria are phenotypically different from suspended planktonic cells of the same genotype. Biofilm growth reactors are engineered to produce biofilms with specific characteristics. Altering either the engineered system or operating conditions will modify those characteristics. The goal in biofilm research and efficacy testing is to choose the growth reactor that generates the most relevant biofilm for the particular study.

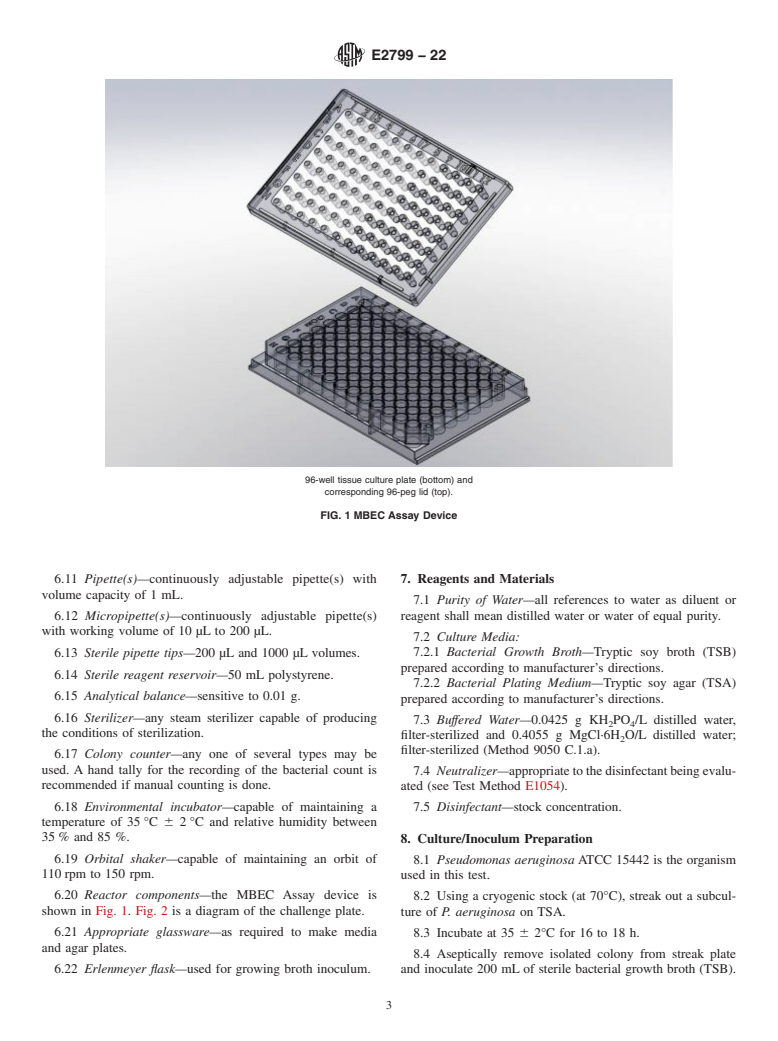

5.2 The purpose of this test method is to direct a user in how to grow, treat, sample and analyze a Pseudomonas aeruginosa biofilm using the MBEC Assay. Microscopically, the biofilm is sheet-like with few architectural details as seen in Harrison et al (6). The MBEC Assay was originally designed as a rapid and reproducible assay for evaluating biofilm susceptibility to antibiotics (2). The engineering design allows for the simultaneous evaluation of multiple test conditions, making it an efficient method for screening multiple disinfectants or multiple concentrations of the same disinfectant. Additional efficiency is added by including the neutralizer controls within the assay device. The small well volume is advantageous for testing expensive disinfectants, or when only small volumes of the disinfectant are available.

SCOPE

1.1 This test method specifies the operational parameters required to grow and treat a Pseudomonas aeruginosa biofilm in a high throughput screening assay known as the MBEC (trademarked)2 (Minimum Biofilm Eradication Concentration) Physiology and Genetics Assay. The assay device consists of a plastic lid with ninety-six (96) pegs and a corresponding receiver plate with ninety-six (96) individual wells that have a maximum 200 μL working volume. Biofilm is established on the pegs under batch conditions (that is, no flow of nutrients into or out of an individual well) with gentle mixing. The established biofilm is transferred to a new receiver plate for disinfectant efficacy testing.3, 4 The reactor design allows for the simultaneous testing of multiple disinfectants or one disinfectant with multiple concentrations, and replicate samples, making the assay an efficient screening tool.

1.2 This test method defines the specific operational parameters necessary for growing a Pseudomonas aeruginosa biofilm, although the device is versatile and has been used for growing, evaluating and/or studying biofilms of different species as seen in Refs (1-4).5

1.3 Validation of disinfectant neutralization is included as part of the assay.

1.4 This test method describes how to sample the biofilm and quantify viable cells. Biofilm population density is recorded as log10 colony forming units per surface area. Efficacy is reported as the log10 reduction of viable cells.

1.5 Basic microbiology training is required to perform this assay.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2799 − 22

Standard Test Method for

Testing Disinfectant Efficacy against Pseudomonas

1

aeruginosa Biofilm using the MBEC Assay

This standard is issued under the fixed designation E2799; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* corded as log colony forming units per surface area. Efficacy

10

is reported as the log reduction of viable cells.

10

1.1 This test method specifies the operational parameters

1.5 Basic microbiology training is required to perform this

required to grow and treat a Pseudomonas aeruginosa biofilm

in a high throughput screening assay known as the MBEC assay.

2

(trademarked) (Minimum Biofilm Eradication Concentration)

1.6 The values stated in SI units are to be regarded as

Physiology and Genetics Assay. The assay device consists of a

standard. No other units of measurement are included in this

plastic lid with ninety-six (96) pegs and a corresponding

standard.

receiver plate with ninety-six (96) individual wells that have a

1.7 ASTM International takes no position respecting the

maximum 200 μL working volume. Biofilm is established on

validity of any patent rights asserted in connection with any

the pegs under batch conditions (that is, no flow of nutrients

item mentioned in this standard. Users of this standard are

into or out of an individual well) with gentle mixing. The

expressly advised that determination of the validity of any such

established biofilm is transferred to a new receiver plate for

patent rights, and the risk of infringement of such rights, are

3,4

disinfectant efficacy testing. The reactor design allows for

entirely their own responsibility.

the simultaneous testing of multiple disinfectants or one

1.8 This standard does not purport to address all of the

disinfectant with multiple concentrations, and replicate

safety concerns, if any, associated with its use. It is the

samples, making the assay an efficient screening tool.

responsibility of the user of this standard to establish appro-

1.2 This test method defines the specific operational param-

priate safety, health, and environmental practices and deter-

eters necessary for growing a Pseudomonas aeruginosa

mine the applicability of regulatory limitations prior to use.

biofilm, although the device is versatile and has been used for

1.9 This international standard was developed in accor-

growing, evaluating and/or studying biofilms of different

dance with internationally recognized principles on standard-

5

species as seen in Refs (1-4).

ization established in the Decision on Principles for the

1.3 Validation of disinfectant neutralization is included as Development of International Standards, Guides and Recom-

part of the assay. mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.4 This test method describes how to sample the biofilm

and quantify viable cells. Biofilm population density is re-

2. Referenced Documents

6

2.1 ASTM Standards:

E1054 Practices for Evaluation of Inactivators of Antimicro-

1

This test method is under the jurisdiction of ASTM Committee E35 on

bial Agents

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct

E2756 Terminology Relating to Antimicrobial and Antiviral

responsibility of Subcommittee E35.15 on Antimicrobial Agents.

Agents

Current edition approved May 1, 2022. Published May 2022. Originally

approved in 2011. Last previous edition approved in 2017 as E2799 – 17. DOI:

2.2 Other Standards:

10.1520/E2799–22.

Method 9050 C.1.a Buffered Dilution Water Preparation

2

The MBEC trademark is held by Innovotech, Inc., Edmonton, Alberta, Canada.

according to Rice et al (5)

3

The sole source of supply of the apparatus known to the committee at this time

is Innovotech Inc., Edmonton, Alberta, Canada. If you are aware of alternative

3. Terminology

suppliers, please provide this information to ASTM International Headquarters.

Your comments will receive careful consideration at a meeting of the responsible

3.1 For definitions of terms used in this standard refer to

1

technical committee, which you may attend.

Terminology E2756.

4

The MBEC Assay is covered by a patent. Interested parties are invited to submit

information regarding the identification of an alternative(s) to this patented item to

6

the ASTM International Headquarters. Your comments will receive careful consid- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

eration at

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2799 − 17 E2799 − 22

Standard Test Method for

Testing Disinfectant Efficacy against Pseudomonas

1

aeruginosa Biofilm using the MBEC Assay

This standard is issued under the fixed designation E2799; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method specifies the operational parameters required to grow and treat a Pseudomonas aeruginosa biofilm in a high

2

throughput screening assay known as the MBEC (trademarked) (Minimum Biofilm Eradication Concentration) Physiology and

Genetics Assay. The assay device consists of a plastic lid with ninety-six (96) pegs and a corresponding receiver plate with

ninety-six (96) individual wells that have a maximum 200 μL working volume. Biofilm is established on the pegs under batch

conditions (that is, no flow of nutrients into or out of an individual well) with gentle mixing. The established biofilm is transferred

3,4

to a new receiver plate for disinfectant efficacy testing. The reactor design allows for the simultaneous testing of multiple

disinfectants or one disinfectant with multiple concentrations, and replicate samples, making the assay an efficient screening tool.

1.2 This test method defines the specific operational parameters necessary for growing a Pseudomonas aeruginosa biofilm,

although the device is versatile and has been used for growing, evaluating and/or studying biofilms of different species as seen in

5

Refs (1-4).

1.3 Validation of disinfectant neutralization is included as part of the assay.

1.4 This test method describes how to sample the biofilm and quantify viable cells. Biofilm population density is recorded as log

10

colony forming units per surface area. Efficacy is reported as the log reduction of viable cells.

10

1.5 Basic microbiology training is required to perform this assay.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item

mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights,

and the risk of infringement of such rights, are entirely their own responsibility.

1

This test method is under the jurisdiction of ASTM Committee E35 on Pesticides, Antimicrobials, and Alternative Control Agents and is the direct responsibility of

Subcommittee E35.15 on Antimicrobial Agents.

Current edition approved April 1, 2017May 1, 2022. Published May 2017May 2022. Originally approved in 2011. Last previous edition approved in 20122017 as

E2799 – 12.E2799 – 17. DOI: 10.1520/E2799–17.10.1520/E2799–22.

2

The MBEC trademark is held by Innovotech, Inc., Edmonton, Alberta, Canada.

3

The sole source of supply of the apparatus known to the committee at this time is Innovotech Inc., Edmonton, Alberta, Canada. If you are aware of alternative suppliers,

1

please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee,

which you may attend.

4

The MBEC Assay is covered by a patent. Interested parties are invited to submit information regarding the identification of an alternative(s) to this patented item to the

1

ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

5

The boldface numbers in parentheses refer to a list of references at the end of this standard.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2799 − 22

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of

the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of Interna

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.